How To Make A Shower Pan On Concrete

How to Build Shower Pans

Larn the professional way to build custom shower pans

![]() Fourth dimension

Fourth dimension

Multiple Days

![]() Complexity

Complexity

Intermediate

![]() Cost

Cost

$101–250

Introduction

Learn how to build a custom-sized, waterproof shower pan for a curved shower enclosure by following these clear, detailed photos and step-by-step instructions.

Tools Required

Materials Required

- one-1/four-in. roofing nails

- i"x3/4"

- 10d galvanized nails

- 1x4

- 2x4

- 2x6

- three-in. drywall screws

- Ceramic floor mix

- Duct tape

- Fiberglass mesh record

- Galvanized expanded metallic lath

- Hardboard siding

- Shower drain associates

- String

- Thin-set mortar

- Tile backer board

- Vinyl membrane

These days, if y'all desire to put in a shower, yous can simply go to a home center and option upwards a fiberglass unit. Earlier that was possible, pros had to build a custom shower pan by mixing and applying mortar, troweling it flat, and laying ceramic shower floor tile.

Although fiberglass units brand shower pans quick and like shooting fish in a barrel, they lack the elegance of a handcrafted mortar and tile floor. So if you'd similar to install a tile shower and are willing to build your own custom shower pan, you lot'll exist able to tile it to match the walls. And with a mortar and tile floor, your shower can be whatever shape. (For instance, encounter How to Install a Glass Cake Shower.) In fact, no affair what its shape, if the shower you accept in heed doesn't conform to the rigid size requirements of a manufactured base, a mortar floor may be your merely alternative.

You'll find that the price of the materials used in a paw-crafted base is roughly the same equally the price of a comparably sized fiberglass pan. The downside is that instead of but plugging a manufactured unit into the opening, yous'll have to do a lot more work. You'll need a couple of days to course and tamp in two layers of mortar, deal with some tricky vinyl membrane liner and and then install the tile. Installing shower pans isn't a project for winging information technology or taking shortcuts. Poorly installed shower pans will leak, and the merely correct way to ready a poor installation is to rip out not but the base only too the shower walls.

The shower pan installed in this project is somewhat complicated, but the fundamental techniques are the aforementioned for even the simplest shower — ane the size of a phone booth. If you have experience with cement and some bones trowel skills, you should be able to practise almost any size shower floor in less than 2 days, excluding tile work.

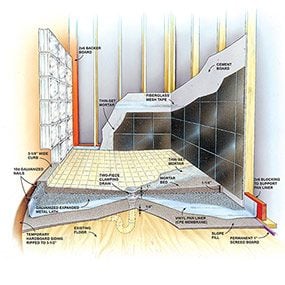

Beefcake of a Mortar Shower Floor

The kickoff layer, chosen a sloped fill, is merely a mortar subfloor. It'south sloped toward a special two-piece clamping-type drain (bachelor at any home center) that is fabricated specifically for a mortar bed shower floor. The sloped fill slants from the drain toward the perimeter of the shower with a slope of one/iv inch per foot. Since our shower had an average width of 3 feet, we sloped up from the 1/4-inch thickness of the drain to a i-inch thickness around the shower walls and curb to become the necessary 3/iv-inch slope.

The second layer, chosen the pan, is a durable CPE (chlorinated polyethylene) membrane. This vinyl liner is turned up at the edges to create a waterproof membrane in the shape of a shallow pan. Water that works its fashion through the grout and the top layer of mortar will flow downwards the slope to be drained through the weep holes of the drain. On height of the pan is a layer of expanded galvanized metal lath to reinforce the mortar. Over the lath, a sloped mortar bed is laid using the same 1/iv-inch-to-the-foot gradient rule we used for the sloped make full.

Shower curbs help by containing water in areas that aren't bordered by walls. If a drain becomes blocked, possibly past a washcloth over the surface, a curb buys you time. It will dam the h2o within the shower for a while before information technology lets information technology run over onto the bathroom floor.

(For a larger version of this drawing, see Additional Data, below.)

Project stride-by-stride (xiv)

Step 1

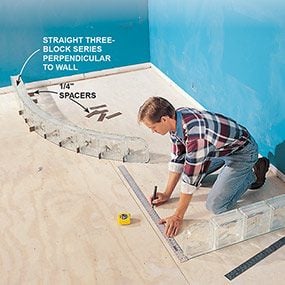

Depict the Flooring

- Draw the outline of the shower floor on the subfloor to utilise equally a pattern for setting the mortar forms.

- Blast an 8d blast adjacent to the wall and strike a 65-inch arc for the curved class board.

Step 2

Confirm the Layout

- Lay out the shower on the subfloor using your stop materials—in this instance, tile and glass cake—to assist define its size and shape for shower pan installation.

Caution!

The shower we designed and installed here weighs up of 1,000 lbs., or most the aforementioned equally a spa with a couple of people in it! If y'all live in an older home with 2x6 or 2x8 flooring joists, you may demand to beef upward the floor with some beams or extra floor joists. If you're unsure, consult a building inspector. And if you have a house that was built in the '70s, it could accept a five/8-inch particleboard underlayment that will demand to be removed earlier starting.

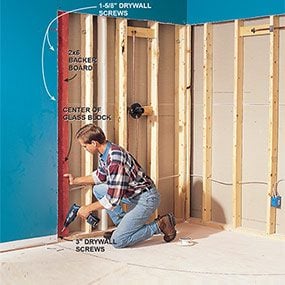

Step 3

Open the Walls

- Cut the drywall and so that the seam of the drywall and cement lath falls halfway backside the drinking glass block.

- Install backers in the stud wall to support the cement lath/drywall seam.

- Cut the top of the drywall at half dozen feet, 2 inches above the plywood flooring to allow for the slope fill and two layers of 3-feet wide cement lath.

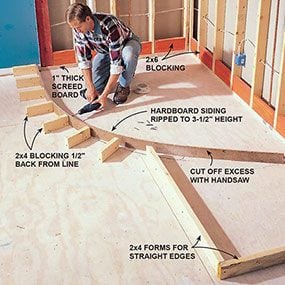

Step four

Class the Curve

- Toe-nail 2x6 blocking at the base of the shower on interior walls to back up the vinyl liner.

- Toe-screw 2x4 blocks to the subfloor every 12 inches and 1/2 inch away from the line to permit for the thickness of the hardboard siding.

- Rip the siding to 3-1/2 inches and spiral information technology to the backside of the blocks for curved curbs.

- Toe-screw 2x4s for straight curbs and cut off the excess hardboard after forming.

- Pro tip: Toe screws are easier to remove after the mortar work is done.

- Nail in permanent 1-inch thick screed boards confronting walls.

- Rough-in the copper plumbing and bleed water lines.

Planning Shower Layout

Keep these elements in mind when you're sizing and positioning your shower:

The tile layout. It'southward easier to determine the size of the shower if your wall tile is selected ahead of time. Since we had 12-inch tile, we made pocket-sized alterations in the size until we had wall lengths that made full tiles come out just behind the inside edge of the glass block.

Shower doors. If your shower will have a door, pick information technology out in accelerate to brand sure the shower opening will accommodate it. Don't forget to allow for the thickness of the tile and the cement board. When you're determining the size of the shower door and the management it should swing, consider other bath doors and fixtures.

Plumbing. It'southward obviously much easier to claw upwards a new shower that is located near existing plumbing. Copper h2o lines, sewer drain lines and vents tin exist hooked upwardly to pipes at a neighboring bathroom. Our shower backed up to a common wall that contained all the plumbing nosotros needed. If you're installing your shower in a remote location, it can be tough to get to the sewer bleed and still go on the shower bleed within the required distance from the drain water vent. You may need to rip out walls or the ceiling beneath the shower to accomplish hook-ups if the next level downwardly is finished. Sometimes plumbing a new bath is more than piece of work than building the shower from scratch.

Footstep 5

Kickoff Layer of Mortar

- Remove the top half of the shower drain and plug the drainpipe with a rag to prevent debris from falling into the plumbing.

- Pack the mortar with a forest float, then screed the first layer of mortar.

- Use removable 1-inch screed blocks along curbs to establish a 1-inch to one/4-inch gradient toward the drain.

- Work the surface smooth with a wood float and smoothen with a steel trowel.

- Let the mortar harden overnight.

Step 6

Lay in the Liner

- Tack up scrap pieces of vinyl liner to protect the actual liner from the sharp edges of plumbing or electrical plates.

- Install the liner, running it up onto the walls at least 6 inches, and nail it to the studs with roofing nails at the top edge.

- Experience the bleed flange bolts with your fingers and draw and advisedly cut the liner to fit just exterior the bolts.

- Cut off the liner confronting the curved edge 1/2 inch below the top of the form.

Step 7

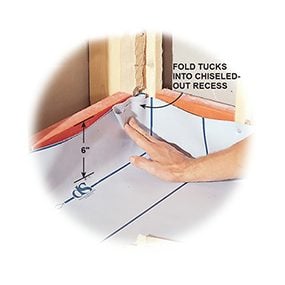

Fold the Corners

- Chisel out the inside corners of the framing to create a recess for the liner folds.

Footstep 8

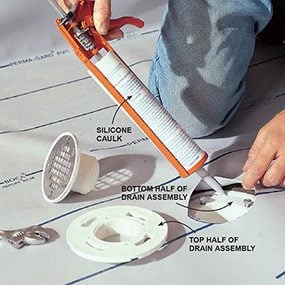

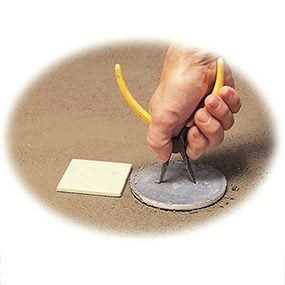

Make a Drain Pigsty

- Cutting out the vinyl liner for the drain with a utility knife, cutting just exterior of the bolt holes.

- Run a bead of silicone caulk around the outer border of the flange.

- Bolt downwardly the tiptop half of the drain associates.

- Encompass the top of the bleed with duct tape to protect it during the installation of the mortar bed and tiling.

Step nine

Attach the Tile Backer Lath

- Install cement board over the vinyl liner and screw information technology to the studs with coated cement lath screws every 8 inches.

- Cutting slots in the cement board to go over curbed areas against the walls.

- Tape the seams with fiberglass tape and thin-ready mortar or mastic.

- Pro tip: When setting the cement board, face the smooth side out. This makes it much easier to spread the tile adhesive and get a flat surface for tiling and for cartoon tile layout lines.

Stride 10

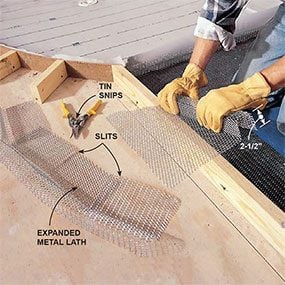

Add together the Metallic Board

- With a pair of tin snips, cutting and lay in galvanized expanded metal lath on peak of the liner only short of the cement board edges.

- Bend 12-inch x iii-foot lengths of board over a 2x4 for curb reinforcement pieces.

- Keep the meridian barely under the grade heights.

- Pro tip: For a curved adjourn, make a serial of slits every 10 inches to aid it curve to the shape of the hardboard course.

- Pro tip:Avoid walking on the board. Its precipitous edges tin puncture your waterproof membrane.

Step 11

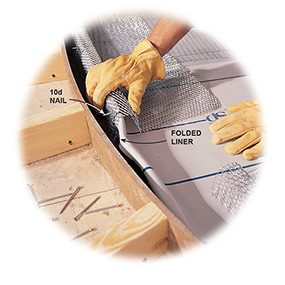

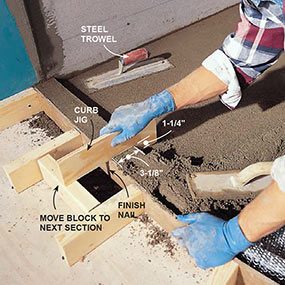

Form the Adjourn

- Fold the vinyl liner and drop the pre-bent curb lath over the tiptop of it.

- Poke a galvanized 10d smash through the lath and top border of the liner to keep it from collapsing while y'all pack the curb with mortar.

Step 12

Cover the Board with Mortar

- Snap chalk lines against the cement board, making them 1-1/4 inch to a higher place the sloped make full.

- Adjust the summit of the drain by screwing it upwardly or down until it is one inch above the top of the slope fill up.

- Pile mortar against the wall and compact it downward to the line.

- Use the packed mortar every bit a guide for screeding off the mortar between the wall and the drain.

- Use the straightedge to locate loftier or low areas.

- Pack in mortar to fill depressions, and scrape off excess in the high spots.

- Utilize a steel trowel to smooth the bed and to tool sharp edges at all corners for a cleaner tiling job.

Step 13

Mortar the Curb

- Pack mortar into the lath with a wood bladder around the folded liner, then screed with a 3/4-inch plywood jig.

- Subsequently screeding, tool the edges of the adjourn with a trowel to obtain crisp edges.

Stride xiv

Adjust the Drain

- Raise the shower drain by unscrewing information technology until it is the same height as the flooring tile.

- Note: You have to do this before the mortar sets.

Boosted Information

- Since this article was offset published, new materials take get bachelor for projects like this. Encounter Pro Tile Tips for more than data.

- Anatomy of a Mortar Shower Floor

Originally Published: November 26, 2020

Source: https://www.familyhandyman.com/project/how-to-build-shower-pans/

Posted by: fischerlableason.blogspot.com

0 Response to "How To Make A Shower Pan On Concrete"

Post a Comment